Industries

FORMOSA SPRING BREWERY

Formosa being a German

settlement, would not have been complete without a brewery. This need was supplied in 1870 by Andrew Rau, just twelve years after the township of Carrick was

incorporated.

From 1870, for a period of

nearly twenty years the brewery changed owners a number of times — recorded names

including F.X. Messner and Anthony

Messner. On Dec. 27, 1899 John Schwartz sold the brewery to Lorenz Heisz,

Buffalo, N.Y. who took possession on Jan. 8, 1900.

Parts of the original

brewery had burned down at different times and were soon rebuilt.

In the earliest days of the

brewery, the malting was done in the upper floor of the brewery. Barley was bought from local farmers, spread on

the floor, and kept warm and moist so that it

sprouted to the exact degree needed.

It had to be turned frequently, day and night. Men had to be in constant

attendance. Some of them slept in a part of the brewery.

Later on the malt was bought from Canada Malting

Co. in Toronto. In 1900 excise tax on malt was 1cD per lb.

On June 12, 1910, Lorenz Heisz sold the brewery to his son Frank A. and his son-in-law, Gustav Tiede,

Buffalo, N.Y. The brewery was known as Heisz and Tiede. They became famous for the outstanding

quality of their products.

On Sunday mornings, after hearing Mass, churchgoers would stop in at the hotels to visit with their friends and have a glass or two of

beer before returning home.

A common sight during those years in the villages, towns and townships within a radius of thirty miles of Formosa was the high-wheeled brewery wagons and the smartly harnessed teams delivering kegs of beer to homes and hotels.

A great deal of ice was needed in those days at the brewery. It was cut from the village pond in winter — cut by hand with long-tooth ice-saws into large squares, and hauled on

horse-drawn sleighs to a storage building which

was part of the brewery. It was well packed in sawdust to keep it from melting until it was needed in the summer. The cellars were

built into a hill with another ice-house

at the back to keep the cellars cold. Frank A. Heisz built an electric motor-driven ice-saw in 1916, which

greatly lightened the work of sawing the large amount

of ice needed.

Prohibition

came into effect in 1916. During the early years of prohibition Heisz and Tiede

manufactured regular beer, and also a light beer of less than 1% alcohol. Regular beer could be purchased through an importing office. The sales office for Heisz

and Tiede was J.E. Wagner

and Son, Buffalo. The purchase order was mailed to the brewery at Formosa and the customer picked up his purchase at the brewery. Often

they drove miles with horse and buggy only to be disappointed when the sales voucher had been delayed in the mails.

In 1922 the

brewery closed completely due to prohibition.

On Aug. 7, 1924 Heisz and Tiede

sold to Conrad Hammer, brewer from Welland,

Ont. In March 1925, under the management of Frank A. Heisz, the renovation of Formosa Spring Brewery was

begun.

Plank floors were replaced with concrete, wooden posts and beams were replaced by steel, new steel water tanks were built by Hunter Bridge and

Boiler Co., Kincardine, Ont. A

6" diameter copper steam coil was installed in the

kettle for heating. Previously the kettle had been fired with wood. A copper top and steam stack were added at this time. The 8 foot wooden mash tun

received a sectional slotted bronze false bottom covering the entire floor

area. A propeller with 10 H.P. motor was installed for mixing the mash. A

refrigeration system complete with cooling coils throughout the cellars was also installed at this time. This replaced the storage

of ice.

In 1926 Charles Deckop and

William Schramm of Buffalo bought the business. Renovations continued.

Early in the spring of 1927 a new bottling shop was built and completely equipped with new semi-automatic equipment, including a Barry Weimiller soaker and pasteurizer, a Henes

& Keller automatic filler, and Liberty

crowner.

New wooden fermenters and larger wooden beer storage tanks were installed.

On March 13, 1927 the first brew was run off and Formosa Spring was back in business again, with the reopening being on June 27, 1927.

Ray Schwartz, of Buffalo was brewmaster, Mat Kempel was cellar-man and Oscar Heisz was

employed in the brewhouse. Christian Rich was fireman.

In the bottleshop were Mike Vogt, Ed Meyer, Edgar Lehman and Isadore Gfroerer. Summer help included Bill and John Downs, Jack Kraemer, Walter and Paul Heisz.

Clara Heisz was stenographer. Frank A. Heisz was

general manager.

The malt was kept in bond and was released by

a custom and excise officer, which

position was held over a period of years by Len McNamara, Barney Beingessner,

Alex McLennan and Oliver Kuntz. It was later taken over by Hanover Customs

Office. The provincial government also had a representative from the Liquor Control Board as well as an inspector of retail sales and warehouse shipments. Harry

McBurney was inspector for many

years, followed by Norman Beingessner and George

Benninger. After changes in the Liquor

Control Act and methods of taxation, the inspector

position was eliminated. In 1927 excise duty on malt was as a lb., malt $1.14 a bushel (36 lbs.) and Oregon

hops 37$ a lb.

In November 1927 Ray Schwartz

resigned as brewmaster and Gustav Tiede returned to take over that position. In May 1933 Gustav Tiede returned to London and Oscar Heisz

was employed as brewmaster, from 1933 until 1966 when

illness forced him into semi-retirement.

The Heisz

family took an active part in the management of the brewery for many years. Frank's three sons,

Oscar, Walter and Paul all graduated from United States Brewer's Academy

in New York City as Master Brewers.

On April 1st,

1941 the American interests sold out to O.V. Craig, Toronto. His interests in turn were taken

over by his brother, Claude Craig, who then

acted as general manager, Oscar Heisz was brewmaster, Walter Heisz was plant superintendent and Paul Heisz

was office manager. Their father, Frank, had

died in 1940.

Over the years more storage tanks

were installed, a large addition made to the

bottle shop and larger more modern equipment installed.

The summers of 1958 and 1968 will

never be forgotten by Formosa residents.

They were the years of the beer strikes, and Formosa being non-union was the

only brewery and retail store open in the province. Thousands flocked to

Formosa. Cars from all over the province drove bumper to bumper along the main street. Demand was so heavy that customers had to be rationed to one case

apiece. Stretching for hundreds of yards the line-up of people waited patiently

to buy a precious case of beer.

In 1968 Claude Craig sold the

brewery to a group of Toronto businessmen.

In 1968 Formosa Spring Brewery

brewed 50,000 gallons of a special beer for the

first Oktoberfest in Kitchener. It was labelled "Oktoberfest Beer" and had a picture of Julius Rauchfuss, president of a German Club in Kitchener, dressed in Bavarian costume, on

the label.

After increasing storage capacity

and finding that further expansion in Formosa was

not feasible, the Formosa executive purchased a 107 acre

site on Highway 400 south of Barrie.

Before moving to Barrie the Formosa plant had reached 80,000 bbls. in sales.

Brewing was carried on seven days a week and bottling six days a week, working round the clock.

A new 600,000

barrel brewery was designed and construction was begun. On May 1st, 1970

the brewery was sold to Benson and Hedges Canada Ltd.

In December 1970 at the annual Christmas party

in Formosa for employees,

Benson and Hedges presented inscribed gold wrist watches to the men who had been employed by Formosa

Spring Brewery for 25 years or more. They were: Oscar Heisz 43 years, Walter

Heisz 42 years, Paul Heisz and Edgar Lehman 40 years, Joseph Kraemer 31 years, Lorne Hundt, Francis Borho,

Nelson Lambertus and Joseph Weiler

30 years.

The new plant at Barrie was in

operation by Jan. 1, 1972. The Formosa Spring

Brewery plant at Formosa was closed on Dec. 31st, 1971.

This was the end of an era. No

more could we enjoy the delightful sweet smell of beer

brewing. We missed the sound of bottling machinery and of trucks loaded with beer leaving for

cities and towns all over Southern and

Eastern Ontario. Most of all we missed the workers and all the activity at the brewery.

Thirty-eight employees moved to

Barrie to work in the new brewery. Most of them

moved their families as well. Their homes in Formosa were soon bought up, mostly by workers at Douglas

Point, the Bruce Nuclear Power

Development.

The new brewery at Barrie was

named Formosa Spring Brewery, and Walter Heisz was retained as brewmaster.

Barry Heisz, Oscar's son, and graduate of Siebel Institute of Technology in Chicago, was assistant brewmaster.

On July 15, 1974, Formosa Spring

Brewery was purchased by Molson's

Breweries. The name has been changed to Molson's Brewery (Ontario) Ltd. Barry Heisz

is now brewmaster, the fourth generation brewmaster in the Heisz

family.

Former Formosa residents still

employed at Molson's, Barrie besides Barry Heisz are Maurice Heisz, son of

Walter, Joseph Weiler, Gerald Borho, Nelson Lambertus, Harvey Weishar,

Harold (Pepper) Voisin, Alvin, Thos. and Elmer Schlosser, Elmer Schill, Dave Schlosser, Joe Schill,

Dennis Benninger and Leo Hauck.

The old plant at Formosa has been

sold by Molson's to Frank E. and Joseph O., sons

of Oscar and great grandsons of Lorenz Heisz. It now carries the name of The Formosa Spring Water

Co. Ltd." Plans are being made for marketing bottled water. Also, part of

it is occupied by the Formosa Spring Fish Products Ltd.and

part serves as a storage facility.

The first brewery at Formosa built

in 1870. Anthony Schumacher on wagon, Frank A. Heisz,

partner in Heisz and Tiede, Cutting ice on the pond to supply the brewery

with enough ice to keep

Tony Obermeyer second from left,

F.X. Messner in buggy. and

for many years manager of Formosa cellars cold during the coming summer.

There was no refrigeration.

Spring

Brewery — until his death in 1940.

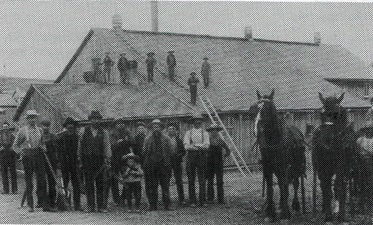

Brewery employees

during war years. Women were employed due to the shortage of

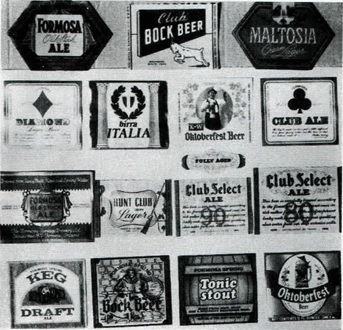

men, many of whom Labels used on different kinds of beer and ale

at Formosa Spring Brewery.

were in the armed services.

Line-up at the beer strike in 1958 Line-up at the beer strike in

1968

Dec. 31st, 1971. The last sales at Formosa Spring Brewery,

Formosa The Formosa Spring

Brewery after final closing as a brewery.

THE SAWMILL AT FORMOSA

As far as we can gather, sometime

in the 1850's, a sawmill was started in Formosa

by John B. Kroetsch. This was the first industry in

Formosa, and naturally was devoted to cutting

pine and other softwoods for building

material. However, it was not until 1864 that the Crown deeded quite a bit of the surrounding land to Mr. Kroetsch, who, as time went on, subdivided the lands into smaller farms, and

again later on these were subdivided into

building lots.

About 1877 W. J. Lynn purchased the

sawmill, producing annually about 600,000

feet of lumber, together with lath and shingles. At his death

the mill was sold to Joseph Brick, who operated for a very short time, and during the 1880s sold the operation to

Joseph Weiler and his son Christian Weiler who

renovated and expanded the business.

A few years later, Joseph Weiler withdrew from the business, and Christian Weiler

operated alone until 1913, when he took his son, Val Weiler into partnership, and again expanded the business, so that during the entire winter the sawmill was cutting up

logs, and for the summer months, the

same employees were kept busy making staves, hoops and apple barrels, which were in great demand at

that time. They also made hand sleighs.

They started a water powered

chopping mill in 1913, and built a harness shop which was run by Philip Weiler and Mr. Schickler. In 1916

a disastrous fire destroyed all these cooperage

buildings, and they were never replaced.

In 1918, on retirement, Christian Weiler sold the sawmill to his sons, Val and Philip,

but unfortunately during the same year Philip died during the influenza

epidemic and Val was left to operate the plant alone. He conducted a very successful

and extensive business. In the years of 1919 to 1923 he also operated a portable sawmill near Wingham,

then at Tinkertown and at Chepstow and

Cargill. From about the year 1930, his sons Edward

and Alfred took over part of the operation.

Adjacent to the Weiler

home was a large barn which, along with cows, horse, pigs and chickens for family use, also housed four teams of heavy draught horses. These were used to pull

sleigh loads of lumber, apple barrels,

and later hard maple squares to the railway station at Mild-may for shipment. Full time teamsters were

employed to look after these horses, to

drive the sleigh loads of finished products, to work in the bush pulling out logs with chains to a convenient

place for loading, and also to haul logs in

from the bush on sleighs. Four long time teamsters were Seraphine Meyer, Herb

Meyer, Bill Peters and Harold Bildstein.

Serry Meyer is now living in Walkerton.

During the depression years, when

sales dropped off until they were non-existent,

Val Weiler Ltd. manufactured many smaller household

items such as kindergarten sets, foot stools,

rolling pins, wooden potato mashers,

butter paddles, wooden spoons, croquet sets, trellises and flower boxes, which were sold very reasonably where ever a market could be found.

At the time of

Val Weiler's death in 1949 the firm was known as Val Weiler Ltd.* until 1960 when Weller Lumber Ltd. was formed.

They purchased large bushlots reselling the land after the timber was removed.

The production was entirely hard maple squares and dimension stock, which was exported to England,

U.S., Holland, West Germany, Russia, and even small shipments to Japan. An extensive

export business, especially to England, had been carried on for many years by Val Weiler.

In the spring of 1971 the assets of the company were sold to Alfred

McGuire who

set up the new company Weiler Dimensions Ltd. They manufacture squares for furniture.

Alfred Weiler died in July1978 at the age of 61. Edward Weiler and his son Arthur are still active in the business.

Edward Weiler has been working in this sawmill for

fifty-two years, his first job being grinding grain in the water-powered mill which was

contained in the same building as the first sawmill.

Many old timers

remember the horse-drawn sleighs loaded with logs, the high singing sound of the saw

and the shrill mill whistle sounding morning, noon and

evening.

For a few years

during the 1940's Val Weiler and his sons owned and operated a sawmill in Perth,

Ontario. The Formosa mill was sold to Gordon Litt who

operated it several years, when unfortunately, it was destroyed by fire. A new building

was erected by Val Weiler across the road from the old site.

So the Formosa

sawmill, the village's first industry, begun in the 1850's, has been operating

continuously until the present day, providing employment and serving a real need in the

community.

* From 1949 the

business was managed by Alfred H. Weiler and owned by

him from 1968 to 1971.

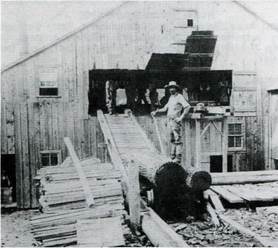

The old Sawmill before 1900. The Lumber Yard behind The Mill

At the Sawmill about 1900

Left to right: Alois Meyer, Frank Schumacher, Tony Beninger, Fred Brick, The

Formosa Sawmill, February 1980

Felix Gutscher, Jos.

Schumacher, Michael Anstedt, Christian Weiler,

Mike Zimmer, Philip Gehring, Wm. Anstedt,

Pete Dentinger, Joseph

Weiler

![]()

![]() Workers at the Sawmill, 1947

Workers at the Sawmill, 1947

Rear row: Mark

Obermeyer, Jerome Hauck, Walter Ditner, Mike Weber,

Walter Dosman, Bob Dietrich, Herb Rumig,

Linus Weber, Jack Bildstein,

Erwin Fischer.

Middle row: Harold Weiler,

Howard Durrer, Dave Meyer, Francis Kuntz, Eugene

Kuntz.

Front row: Raphael Meyer, Ken Dickison, Seraphin Schmidt, Edward Weiler,

Val Weiler, Harold Bildstein,

Alfred Weiler, Melvin Zimmer, Angus McCleod, Gerald

Schmidt, Dave Gill.

TILE MANUFACTURE

Joseph Kraemer was the first manufacturer of

concrete tile by production line

machinery in the early 1920's.

In 1860-70 quite a number of

land drains were installed using logs with large holes bored through the centre. The

ends of these 8' and 10' timbers were fitted as male and female joints.

It is known that Henry Mosack,

son of the Mosack hotel people, introduced at about the turn of the century,

the use of Portland Cement to this area From

then on concrete could be used for building walls, bridges, stabling, sidewalks, etc.

WOOLEN MILLS

About all that is known of a woolen mill

operating at Stoney Creek (Formosa). Jacob Messinger

operated a mill here prior to 1870 at which time he moved operations to Hanover. No reference of later operation could be found.

SIDEWALKS IN THE VILLAGE

It is difficult to ascertain the exact year

that the first wooden sidewalks were

constructed.

Various photos would indicate that as early as

1880 ribbons of sidewalks had

been built by the laying of long sawn timbers with plank crosses nailed

thereto. These were in use on the main street until about 1915 and on the school hill until 1923.

Gradually, as concrete (Portland Cement) was

introduced, the plank sidewalks, which were worn out or broken, were replaced

with the more permanent

concrete material, Gravel was hauled from local pits by team. Cement was shipped by rail to Mildmay and teamed to Formosa. It was packed into round white cotton cloth bags and

tied with a short, soft wire tie. The

cement was mixed by hand with round mouthed shovels and blocked in 6' x 5' squares.

Christian Weiler

could be called the father of sidewalks, as he instigated and supervised the laying of the new

cement sidewalks.

BUTCHERING

From fall until spring local men would act as

butchers to kill and process several

pigs at practically every home. Three or four different types of sausages were made (bratwurst, liverworst, blood pudding and schwardermauger). Hams were home cured and smoked in the

small smoke-house to be found on every property. Lard was

rendered in large iron kettles.

Each of these so called professional butchers

had their own recipes for seasoning

meats, and great pride was taken in their prowess.

There is a

story of two groups in a neighbourhood. On the night

of butchering

group one invited group two to taste their sausage. Of course, group two declared that the

sausage was not nearly as good as their own. Not until the next morning when they found

some of their sausage missing did, they realize that group one had stolen it and that they had

eaten and

criticized their own sausage.

Usually a card

game with an abundance of drinks ended the long day which started with out-door

fires at 6:00 a.m.

Some of the

earlier butchers in Formosa were the Weilers (Alois

and Matthew), George Weiss, Charles Waechter, Herbert Beninger,

Alphonse Zimmer and Leander Beninger. For some years Mike Goetz and later Isadore Weiss peddled meat house

to house.

Shown here is a Tailor Shop near the mill Pictured here is the modern Rettinger Meat Market on

Pond. Alois Weiler,

brother of Chris, was one Con. 12, Culross

Twp. Operated by Dave Rettinger

Of

the tailors. Later this shop was used as

a

Butcher

shop operaed by Matthew Weiler

and

Later George Weiss.

Another modern Meat Market near

Formosa is Elora Road Meats on the Elora Road,

owned and operated by the Leo Batte family.

QUILTING BEES

Quilting Bees

were popular especially in the winter time. Neighbourhood women would gather at various

homes to quilt the patchwork quilts made of scraps of material left from

dressmaking; and to tie the heavier comforters made of suit and coat material patches.

DRESSMAKING

Dressmaking was

done by various women proficient at their work in their own homes or going to

customers' homes. At times, a week or so was spent in one home by the seamstress,

making dresses, suits, etc.

MILLINERY

Beautiful hats were made by ladies

skilled in this work. Millinery shops were also conducted from the Messner store.

LOGGING BEES

Since no one

had much money to pay for wages, exchange of work was naturally in order among neighbourhoods. Usually logging bees were held for clearing land, burning

logs, putting up barns, butchering, threshing, harvesting

and assisting where sickness or misfortune had befallen someone in the neighbourhood.

CIDER MILLS

One of these

early commercial mills was conducted on the farm premises of Peter Kuntz where the horse power was used to grind the apple pulp and to apply the pressure

to the press. The John Ditner farm also had an operative mill where cider

was manufactured for many years.

From about 1920

to 1940 Joachim Kraemer owned and operated an extensive Cider Mill and an Apple Butter

cookery. Patrons would supply the diced apples for the filler to be added to the boiled cider. Apple

butter in huge

quantities was enjoyed in most homes. At this establishment, a large oil

engine supplied the motive power while a huge stationery steam boiler supplied

the cooking heat. During the fall season up to a dozen men would be employed.

Shortly after

World War II, Herb Kuntz and Andrew Opperman acquired the large building on Lot No. 1, Plan

282, Formosa, and converted same into a plant to wash and wax rutabaga for shipment to the American city produce markets. Each

fall and winter local farmers would deliver wagons and sleigh-loads to the plant

where they were processed, bagged (50lbs per bushel) reloaded into railway box

cars in Walkerton and in later years into refrigerated produce trucks, hauling out

loads of up to 800 bushels.

The

Turnip Waxing Plant at Formosa

The plant

changed hands several times, the last owner/operator being Bert Ernewein. Today only a few farmers in the area grow

this crop. Mr. Ernewein specializes by growing large acreages each

year.

Following the 1st World War, a great deal of

testing took place in connection with

limestone rock which is found in abundance in and about Formosa.

A Company generally known as the Hydro began

operating a large crusher plant

at the rock cut some two miles north of the village during the summer of 1920. As high as 50 men were

employed during the construction of buildings and plant. Wages at that time

had reached to an all-time high of 60˘ per hour for carpenters. Work time consisted of 10 hours per day, 6 days per week. Buildings consisted

of Crusher, 65 feet high, 30' Belt Conveyor,

Dynamite Storage, Bunk Houses and Blacksmith Shop. A railroad siding with

connection into C.N.R. line near Walkerton was constructed. In order to

loosen and break up the rock material a drilling rig was employed. As high as 90 holes 4 inches in

diameter would be drilled to a depth of

30 feet. Four to five tons of blasting powder would be packed into these well-like holes and set off

at one time. These blasts could be heard

and felt for many miles. Thousands of tons of rock would be loosened to be fed into crushers which

could chew up large boulders. The balance

wheels of the crusher were 2 feet wide, one foot thick and built to a diameter of 10 feet. Peak

production of 24 rail cars holding 50 tons each were shipped per day. Most of the crushed rock was shipped to the Steel Mills at Hamilton. Rail roads also

bought huge quantities for roadbeds. A

considerable amount was also shipped to the Hanover Cement Works to be used in manufacture of

Portland Cement.

This venture

which seemed to blossom overnight ground to a halt some three of four years later.

The machinery spur line was removed and most of the buildings decayed within a 10-year

period. About 40 years later a holding company purchased several hundred acres of the outcropping of rock in this area, so who

knows when further development might take place.

Among the

many who were employed at this project were Albin Schmidt, Steve Kraemer,

Harry Schill, Frank Voisin,

Anthony Schnurr, Bill Peters, Ed Spielacher,

Edgar Lehman, Frank Obermeyer and Stanley Bauman.

BLACKSMITH SHOPS

For many years Alois Meyer operated a blacksmith shop in the southern end of the village,

across the street from the general store.

John Hundt, and later his son William, served

the public in their blacksmith shop which was on the site of the present

Gerald Weishar residence.

Harry Fedy's shop

was in the northern end of the main street. That building was demolished last year, after

heavy snow caused it to cave in.

John

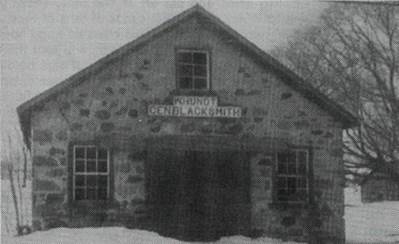

Hundt in his shop. He and his helper could put 106 William Hundt’s

Blacksmith Shop

Harry Fedy's Blacksmith Shop.

Harry J. Fedy, Formosa Blacksmith 1917 - 1978